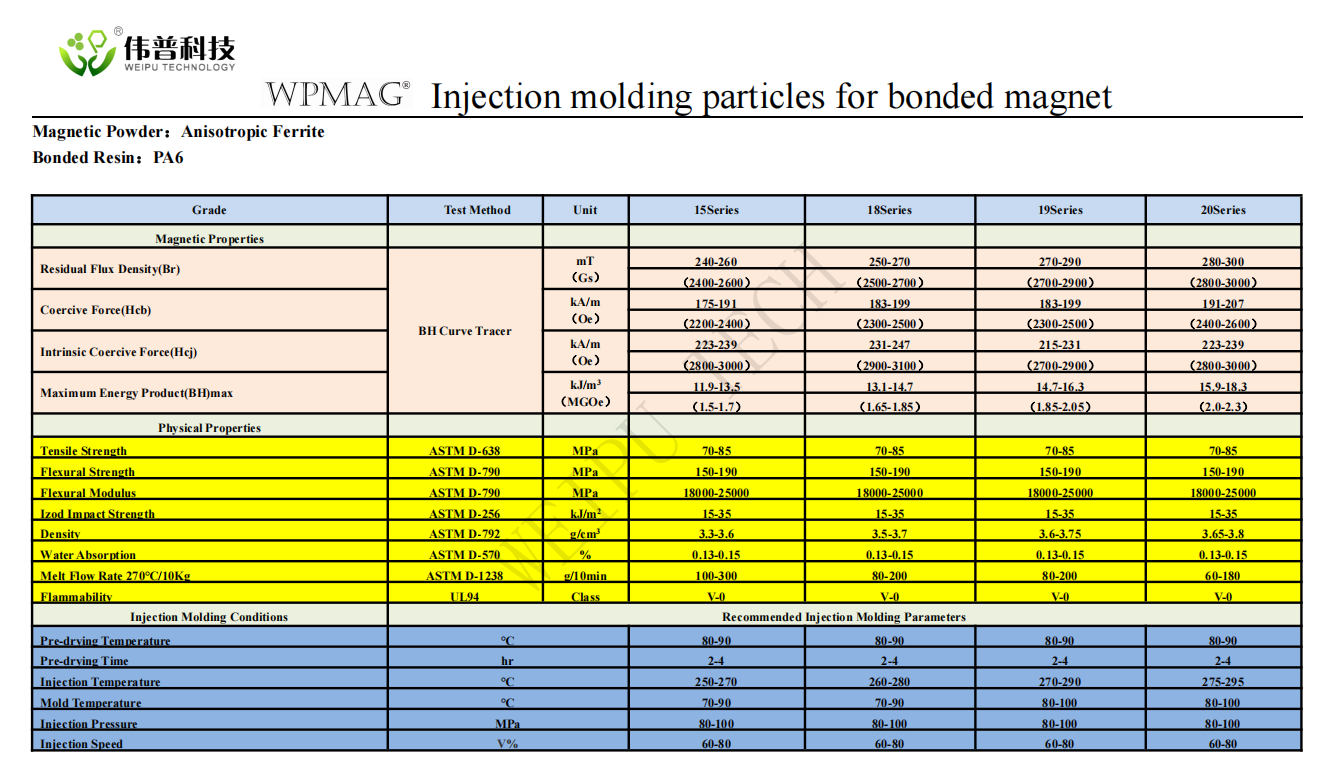

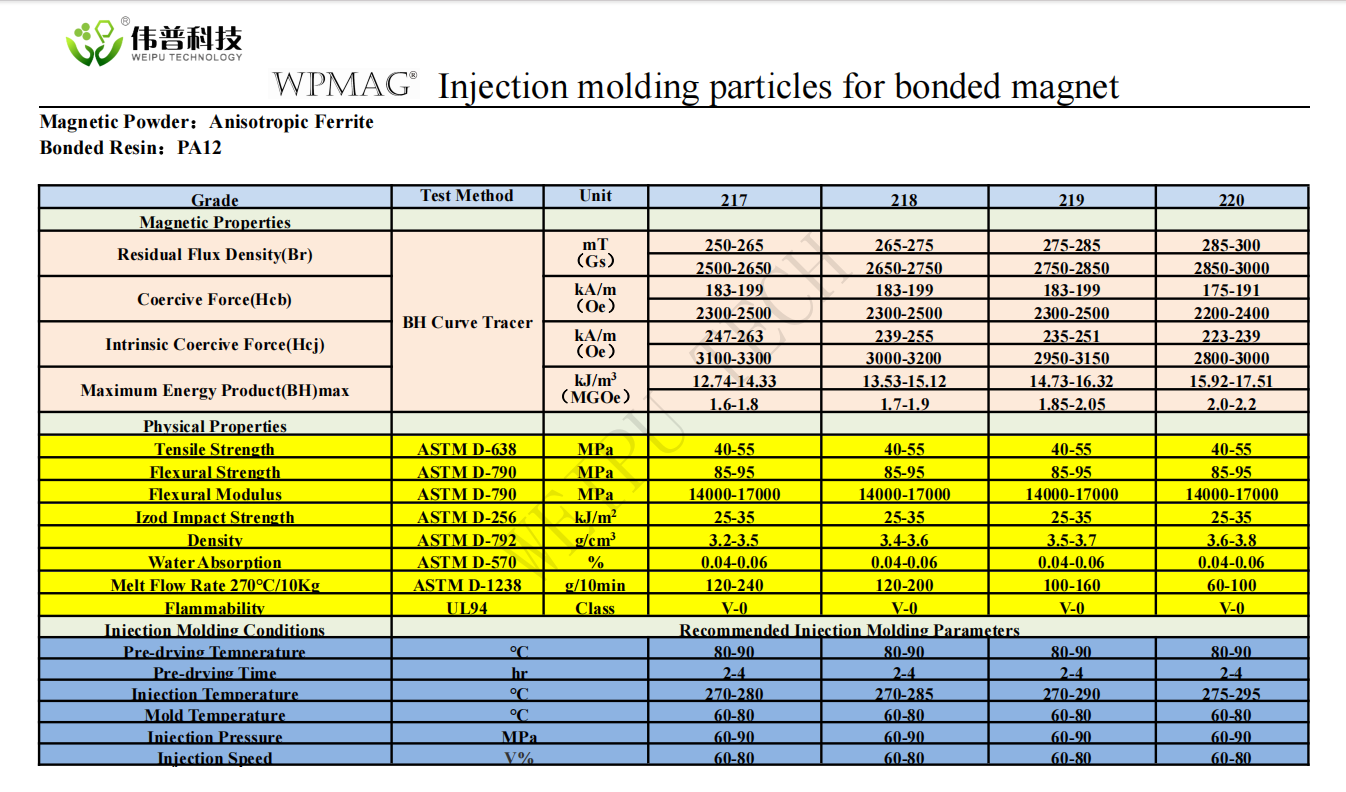

Injection molding ferrite particles for bonded magnet

Injection molding ferrite particles for bonded magnet

(BH)max: 9.6-18.4kJ/m³(1.2-2.3MGOe)

Br: 220-300mT(2.2-3.0kGs)

Hcb: 175-239kA/m(2.2-3.0kOe)

Hcj: 207-271kA/m(2.6-3.4kOe)

![]() WEIPU TECH PA6 Injection molding particles for bonded magnet.pdf

WEIPU TECH PA6 Injection molding particles for bonded magnet.pdf

![]() WEIPU TECH PA12 Injection molding particles for bonded magnet.pdf

WEIPU TECH PA12 Injection molding particles for bonded magnet.pdf

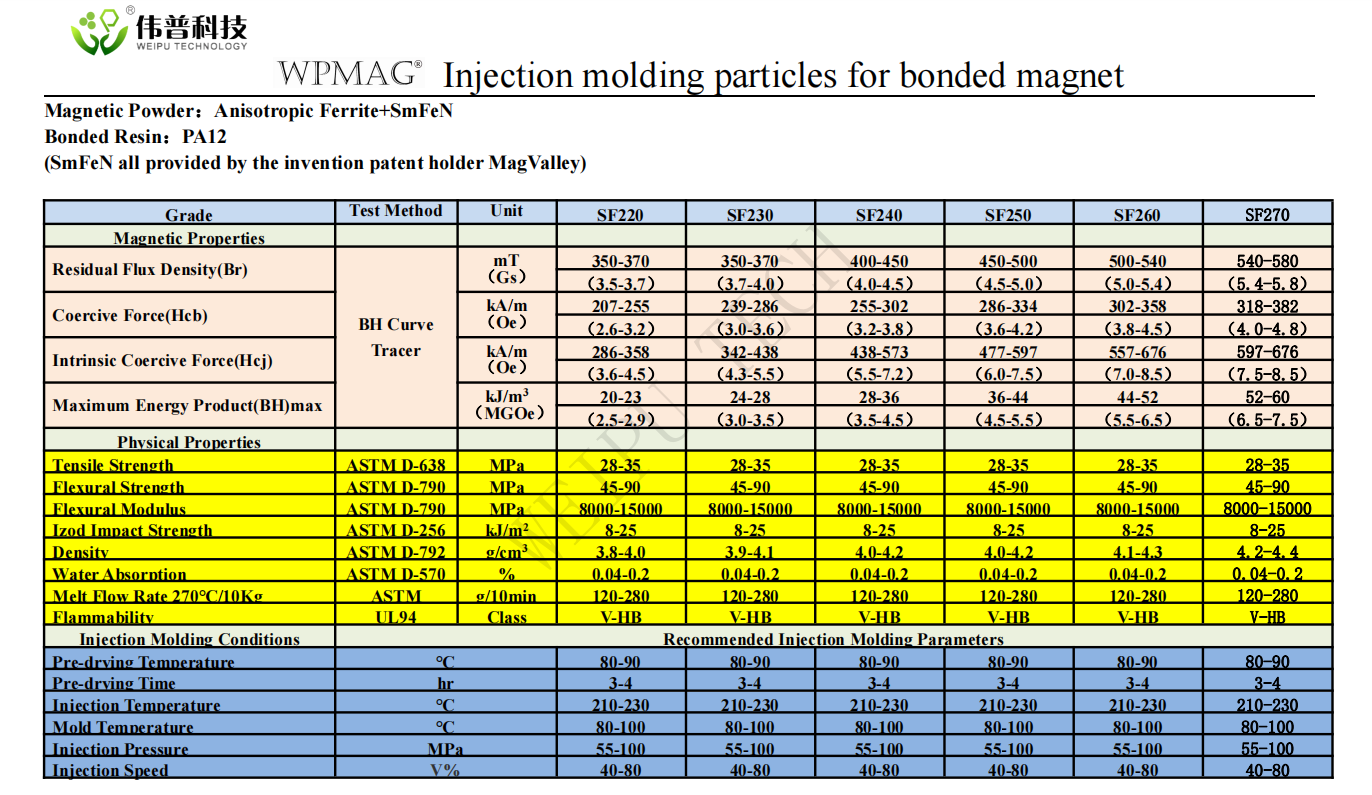

Rare earth hybridization Injection molding ferrite particles for bonded magnet

(BH)max: 16.0-60.0kJ/m³(2.0-7.5MGOe)

Br: 350-580mT(3.5-5.8kGs)

Hcb: 175-302kA/m(2.2-3.8kOe)

Hcj: 286-676kA/m(3.6-8.5kOe)

![]() WEIPU TECH Injection molding SmFeN hybrid Ferrite particles for bonded magnet.pdf

WEIPU TECH Injection molding SmFeN hybrid Ferrite particles for bonded magnet.pdf

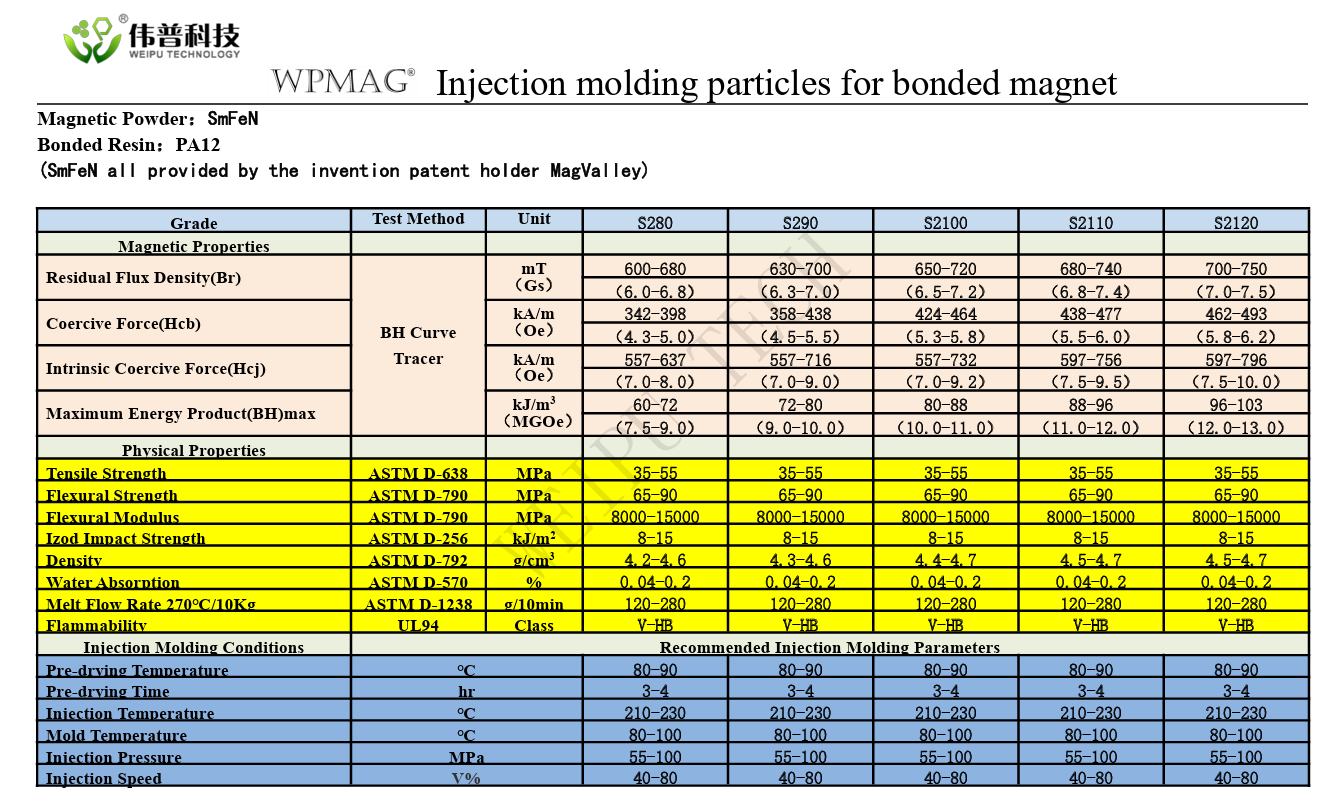

Rare earth samarium iron nitrogen injection magnetic particle material

(BH)max: 60-104kJ/m³(7.5-13MGOe)

Br: 600-750mT(6.0-7.5kGs)

Hcb: 239-493kA/m(3.0-6.2kOe)

Hcj: 557-796kA/m(7.0-10.0kOe)

![]() WEIPU TECH Injection molding SmFeN particles for bonded magnet.pdf

WEIPU TECH Injection molding SmFeN particles for bonded magnet.pdf